Today started with a lot of learning about how much I didn't know.

First, I waited far too long to crack open our window quote, and learned that the proposed window sizes were all different than specified by the architect, to fit into standard sizes. The thing would have looked ridiculous. But we need to know the window sizes to finalize post locations, which affects exactly where we drill giant holes in the foundation.

Second, the rental shop said their hammer drill bits weren't good for rebar. Wut? All my little ones claim to be! Hmm. So we didn't rent.

But all of this stuff is on the critical path!

For the windows, we called all over tarnation and found a lumberyard with a window rep on staff on Saturday. We dropped off our plans with him, and hit the road.

As Eliot drove up to Cle Elum, I spent an hour browsing the Internet to find drill bits that can eat rebar and are long enough to do our ridiculous job. I never quite found the right things, and already had $500 of stuff in my cart.

In Cle Elum, we found drill bits that were supposed to be good for rebar, that were about 3" shorter than we need. We realized that we could drill most of the holes, then do the last 3" (which won't have rebar) with rental equipment later.

And then the window quote came in, with all the windows the right size! So we went from no numbers and no tools, to plenty of work to do.

Siggy brought his bike.

...and looked for frog holes.

When we arrived, this turkey was leading us around slowly.

After we left her alone, she gathered up a dozen chicks and led them away. Cute! The photo is terrible, but some of those blobs are cute little chicks.

Eliot and Calvin got the HVAC pad forms done, and got rebar ready to go in the other forms.

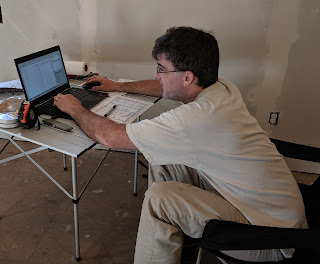

I spent five hours at a desk, carefully measuring out the locations of the 20 holes we need to drill in the foundation. Then measuring, and re-checking those results again. I'm pretty sure they're right.

Eat, drink, and be merry, for tomorrow we drill concrete.

As the old saying goes, measure 3 times, cut 4 times!

ReplyDelete